A Closer Look at Fluidized Bed Incineration

6/10/2019

Fluid bed incineration is a waste disposal process that’s both economical and environmentally friendly. Built-in heat recovery methods lower energy needs and operating costs alike. The energy by-product can even be utilized separately from the incinerating system.

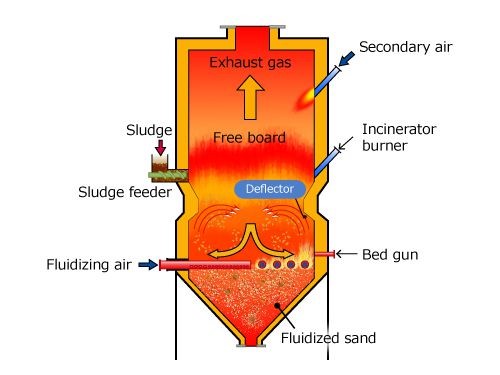

The term “fluid bed” refers to the way the solid waste is kept in a turbulent motion by an upward stream of moving air. This mix of solids and air behaves as a fluid and has the characteristics of a boiling liquid. The vigorous mixing of the solids and gases means that temperature is evenly distributed. It provides a big surface area where heat can be transferred rapidly. Combustible solids are in direct contact with oxygen, meaning that they burn rapidly and completely, shortening the time needed for the process. The bed has a huge heat reservoir capacity allowing for almost instant start-up with no auxiliary fuel needed when the unit has been shut down for a short time. The rapid incineration of waste means that these units can process huge volumes.

The heat that’s generated is recovered in a steam boiler, steam is produced and is used to generate electricity. Some units feed it back into the public grid. Emissions are monitored closely to ensure that the flue gases comply with environmental regulations.

The term “fluid bed” refers to the way the solid waste is kept in a turbulent motion by an upward stream of moving air. This mix of solids and air behaves as a fluid and has the characteristics of a boiling liquid. The vigorous mixing of the solids and gases means that temperature is evenly distributed. It provides a big surface area where heat can be transferred rapidly. Combustible solids are in direct contact with oxygen, meaning that they burn rapidly and completely, shortening the time needed for the process. The bed has a huge heat reservoir capacity allowing for almost instant start-up with no auxiliary fuel needed when the unit has been shut down for a short time. The rapid incineration of waste means that these units can process huge volumes.

The heat that’s generated is recovered in a steam boiler, steam is produced and is used to generate electricity. Some units feed it back into the public grid. Emissions are monitored closely to ensure that the flue gases comply with environmental regulations.